Autonomous driving robots

designed for

factory automation

AGV

AGV Outline

The AGV series can:

Be site-customized.

Be controlled easily using the control system.

Control positioning precisely.

Perform positioning and obstacle detection using sensor technology.

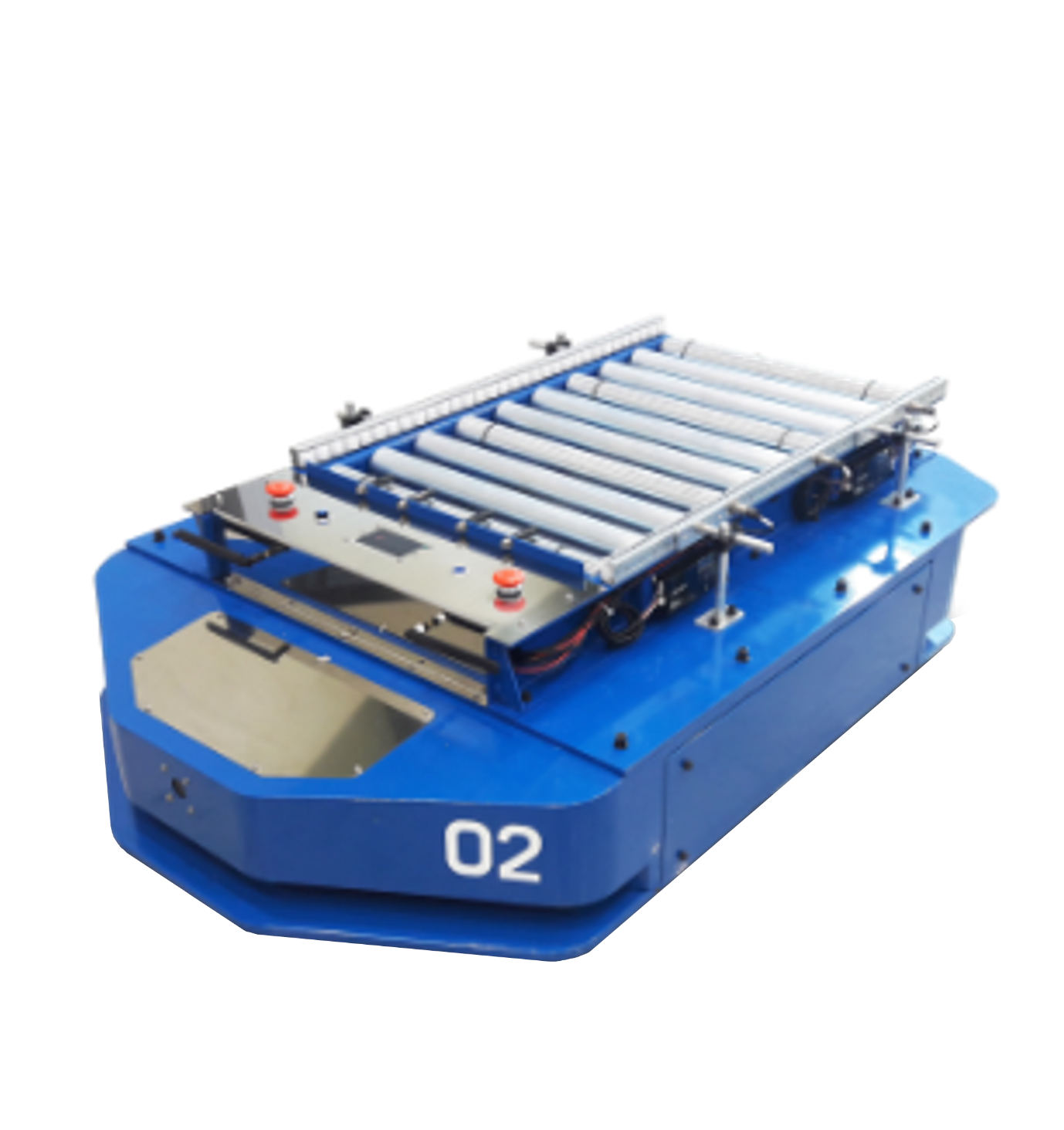

PSV1000

1,000 kg-class conveyor type robot

suitable for factory automation

Features of Robots

for Factory Automation

The AGV series has various guided approach technologies.

It has models for precise position control and various loading types.

Positioning and obstacle response using various sensor application technologies are possible.

It provides an environment where people and robots co-work.

It is possible to control multiple robots using self-developed FMS centrally.

It is possible to operate the SCADA system for compatibility with industrial equipment.

Technology Using the Guidance Methods

Guidance Methods

Spot guidance method

Optical guidance method

Self-guidance method

Image processing situation recognition method

Lineup

AGV - QR guidance, laser guidance

AMR - 2D SLAM, 3D SLAM

Products

Incorporating the characteristics of the AGV and AMR

SLAM (driving) + docking (QR or LASER)

Technology

Driving · Management

Image processing method

+ QR-based autonomous drivingPrecision docking integrating QR, 3D Depth Camera, etc

Autonomous driving position error range within ± 50 mm

Within the error range of QR-guided driving position ± 5 mm

Robot status check

(condition, battery, location)Precision docking integrating QR, 3D Depth Camera, etc

Automatic charging management based on the remaining battery level

Easy location initialization

Stability · Convenience

Deceleration with obstacle detection /

Emergency button embeddedConstant grounding and loading stability through six-wheel driving

(4 front / rear auxiliary casters, 2 driving wheels)

Easy installation

- Map building and route / destination settingFlexible layout changes

Customer specific requirement production

Various loading types such as conveyors and lifts

User interface (UI) tailored to customer needs and preferences

Control System

Task assignment

Map saving

Robot path planning

Robot traffic management

Compatible with various industrial protocols

Automatic door interlock / control

Work statistics

Robot status

Robot location

Detailed Specification

- Basic Specification

- Size (LWH) 1,100 x 1,660 x 350 mm

- Loading / Unloading Type Conveyor

- Loading Weight 1,000 kg

- Following Method SLAM, QR + SLAM, QR

- Speed Max. 1.0 m/s

- Driving Method DD Type

- Charging Hours 2hours

- Operating Hours 8hours

- Battery & Motion Performance

- Battery 24 V 80 A / 48 V 80 A

- Charging Method Automatic charge / Manual charge

- Stop Precision - SLAM Within the error range of ± 50 mm

- Stop Precision - QR Within the error range of ± 5 mm

- Max. Gradability 5 ˚